Read more

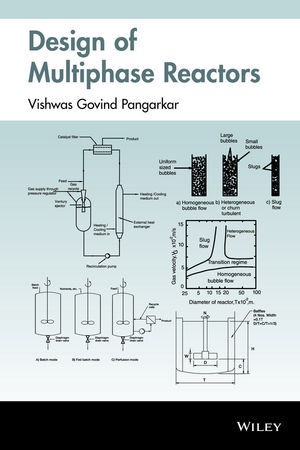

"This resource offers a primer on simple design methods for multiphase reactors in the chemical process industries, particularly the fine chemicals industry. It provides the process design engineer with simple yet theoretically sound procedures. Different types of multiphase reactors are dealt with on an individual basis. The book focuses on the problem of predicting mass transfer rates in these reactors. It also contains finally worked examples that clearly illustrate how a highly complex MPR like the Stirred Tank Reactor (STR) can be designed using simple correlations which need only a scientific calculator"--

List of contents

Foreword xv

Preface xvii

1 Evolution of the Chemical Industry and Importance of Multiphase Reactors 1

1.1 Evolution of Chemical Process Industries 1

1.2 Sustainable and Green Processing Requirements in the Modern Chemical Industry 4

1.3 Catalysis 9

1.4 Parameters Concerning Catalyst Effectiveness in Industrial Operations 17

1.5 Importance of Advanced Instrumental Techniques in Understanding Catalytic Phenomena 20

1.6 Role of Nanotechnology in Catalysis 21

1.7 Click Chemistry 21

1.8 Role of Multiphase Reactors 22

References 23

2 Multiphase Reactors: The Design and Scale-Up Problem 30

2.1 Introduction 30

2.2 The Scale-Up Conundrum 31

2.3 Intrinsic Kinetics: Invariance with Respect to Type/Size of Multiphase Reactor 34

2.4 Transport Processes: Dependence on Type/Size of Multiphase Reactor 34

2.5 Prediction of the Rate-Controlling Step in the Industrial Reactor 35

2.6 Laboratory Methods for Discerning Intrinsic Kinetics of Multiphase Reactions 35

Nomenclature 44

References 45

3 Multiphase Reactors: Types and Criteria for Selection for a Given Application 47

3.1 Introduction to Simplified Design Philosophy 47

3.2 Classification of Multiphase Reactors 48

3.3 Criteria for Reactor Selection 48

3.4 Some Examples of Large-Scale Applications of Multiphase Reactors 55

Nomenclature 80

References 81

4 Turbulence: Fundamentals and Relevance to Multiphase Reactors 87

4.1 Introduction 87

4.2 Fluid Turbulence 88

Nomenclature 91

References 91

5 Principles of Similarity and Their Application for Scale-Up of Multiphase Reactors 93

5.1 Introduction to Principles of Similarity and a Historic Perspective 93

5.2 States of Similarity of Relevance to Chemical Process Equipments 94

Nomenclature 102

References 104

6 Mass Transfer in Multiphase Reactors: Some Theoretical Considerations 106

6.1 Introduction 106

6.2 Purely Empirical Correlations Using Operating Parameters and Physical Properties 107

6.3 Correlations Based on Mechanical Similarity 108

6.4 Correlations Based on Hydrodynamic/Turbulence Regime Similarity 116

Nomenclature 135

References 138

7A Stirred Tank Reactors for Chemical Reactions 143

7A.1 Introduction 143

7A.1.1 The Standard Stirred Tank 143

7A.2 Power Requirements of Different Impellers 147

7A.3 Hydrodynamic Regimes in Two-Phase (Gas-Liquid) Stirred Tank Reactors 148

7A.3.1 Constant Speed of Agitation 150

7A.3.2 Constant Gas Flow Rate 150

7A.4 Hydrodynamic Regimes in Three-Phase (Gas-Liquid-Solid) Stirred Tank Reactors 153

7A.5 Gas Holdup in Stirred Tank Reactors 155

7A.5.1 Some Basic Considerations 155

7A.5.2 Correlations for Gas Holdup 164

7A.5.3 Relative Gas Dispersion (N/NCD) as a Correlating Parameter for Gas Holdup 165

7A.5.4 Correlations for NCD 166

7A.6 Gas-Liquid Mass Transfer Coefficient in Stirred Tank Reactor 166

7A.7 Solid-Liquid Mass Transfer Coefficient in Stirred Tank Reactor 175

7A.7.1 Solid Suspension in Stirred Tank Reactor 175

7A.7.2 Correlations for Solid-Liquid Mass Transfer Coefficient 191

7A.8 Design of Stirred Tank Reactors with Internal Cooling Coils 194

7A.8.1 Gas Holdup 194

7A.8.2 Critical Speed for Complete Dispersion of Gas 194

7A.8.3 Critical Speed for Solid Suspension 195

&n

About the author

Vishwas Govind Pangarkar was Professor and head of the Chemical Engineering Department of the University Institute of Chemical Technology in Mumbai, India. He has been actively engaged as a consultant in the chemical industry since 1974 for both Indian and overseas companies. He is the (co)author of three books and over 130 professional papers. He is the only Indian winner of both Herdillia and NOCIL Awards of The Indian Institute of Chemical Engineers, which are for excellence in such diverse fields as basic research and industrial innovations.

Summary

This resource offers a primer on simple design methods for multiphase reactors in the chemical process industries, particularly the fine chemicals industry. It provides the process design engineer with simple yet theoretically sound procedures. Different types of multiphase reactors are dealt with on an individual basis.